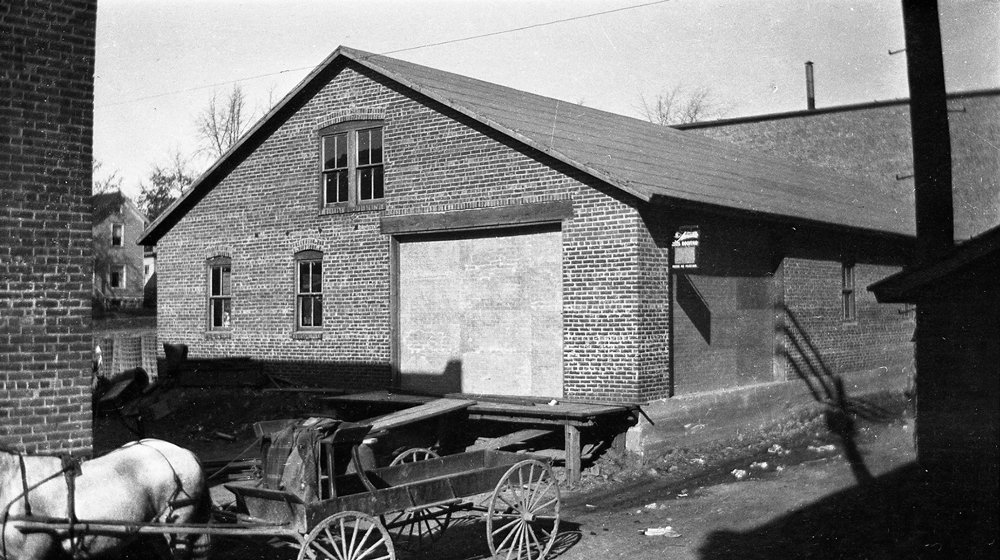

An article in the Monroe Sentinel on March 20, 1867 gave a few statistics about the wagon manufacturers in Monroe at the time. The newspaper took “pains to ascertain the extent” of the firms and found out “the figures obtained from the leading establishments engaged in this important branch of mechanism go beyond our former ideas on the subject. We have, for some time, regarded wagon-making as a leading trade in Monroe, judging from the number of wagons we have seen passing our office on their way to the place of shipment, but were agreeably surprised to learn that our estimates have been entirely too small.” It is important to remember that all of the work on these products had to be done by hand.

The first company to be mentioned was the Monroe Manfacturing Company, which was turning out six wagons per week. They intended to put up 300 wagon in the year. The average cost of a wagon was $90, making a total of about $27,000 for the year. The company also intended to build 30 or 40 sleighs at an average cost of $35 each, totaling about $1,400. The company also intended to manufacture about 100,000 feet of white oak lumber into felloes (the outer rim of a wheel, to which the spokes are fixed) that were to be shipped to other manufacturers in Wisconsin and Illinois cities. The article went on to state that, “The wagons built by this establishment are well made and finished in good style — the material all being selected by competent judges.”

Harris Pool Manufactory “had a reputation of turning out as good wagons as any shop in the state.” They were turning out four wagons per week at an average cost of $100 each. Mr. Pool was making a great many spring-wagons of various kinds. He had put up 13 buggies and three spring wagons since the beginning of the year at an average of $160. During the past winter he had made 17 cutters and sleighs averaging $50 each. He had produced and sold 100 lumber wagons and 20 spring-board wagons the previous year. He planned to make at least 150 wagons in 1867.

Both Monroe Manufacturing and Harris Pool also did an immense amount of repairing to all sorts of vehicles and machinery.

Fred Buehler was a less pretentious, but thriving establishment, who also turned out wagons. He turned out well made, ironed, and painted wagons at the rate of four each month. He also produced 12 to 15 sleighs during the winter. His wagons sold for $100 each and he received $35 for each sleigh. He also did a great deal of repairs.

The article also mentioned that there were several other shops within the village including George Adair, Cobb, and Lance [probably Lanz or Lantz] & Ruegger who turned out from 1 to 3 wagons a month. This would add a total of from 45 to 50 wagons of all kinds in a year.

The article also included a table that recapitulated how many wagons were produced in Monroe per year and the cost. All manufacturers combined produced about 560 a year with an average cost of from $90 to $100 each, which made a total cost of $52,700. The Pool and Buehler establishments were the only ones who produced spring wagons, which raised the cost of each wagon.

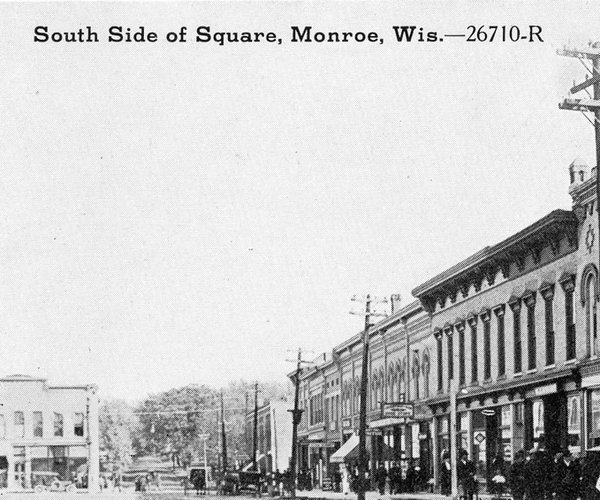

The editor said there was “probably no county in the State that has superior advantages, in the way of timber, for the manufacture of wagons, and we venture the assertion that there is not a town of its size in the Western States that can show bigger figures in this branch of business than Monroe.”

The article also answered the question as to what happened to the newly built wagons. It said that, “Some find their way to less favored localities in Illinois and Wisconsin, many are sent to Iowa, Missouri, and Nebraska and not a few cross the plains for Idaho [and] Montana.

The editor also predicted that when the Milwaukee & Prairie du Chien Railroad extended to Dubuque, as it seemed they would do, Monroe, even with the lack of water power, would be a lively manufacturing town. Since wood was plentiful and convenient, and a sufficient quantity of water was available, he concluded that, “we would rather not have a water course, and that we do want the railroad extended.”

Wagon manufacturing was prominent in Monroe for many decades. A look at the industrial census for Monroe in 1860, as summarized in Becoming A Village: Monroe in the 1850s, shows four different firms who manufactured wagons. Jeremiah Chandler, Hess & Lantz, James McLane, and S. C. Russell collectively employed a total of 11 men that year. The census schedule tells how much the owners had invested in their business, how many people they employed and how much the employees were paid, what raw material was used and its value, and how much they produced and their value. The coming of the automobile and the changing technology certainly altered what was manufactured in Monroe.

— Matt Figi is a Monroe resident and a local historian. His column will appear periodically on Saturdays in the Times. He can be reached at mfigi48@tds.net or at 608-325-6503.